Enhancing paracetamol compressibility using the co-drying technique: Impact on tablet release profile from direct compression

DOI:

https://doi.org/10.5530/gjpb.2024.3.7Keywords:

Poor compressibility, co-processing, flow ability, direct compression, paracetamolAbstract

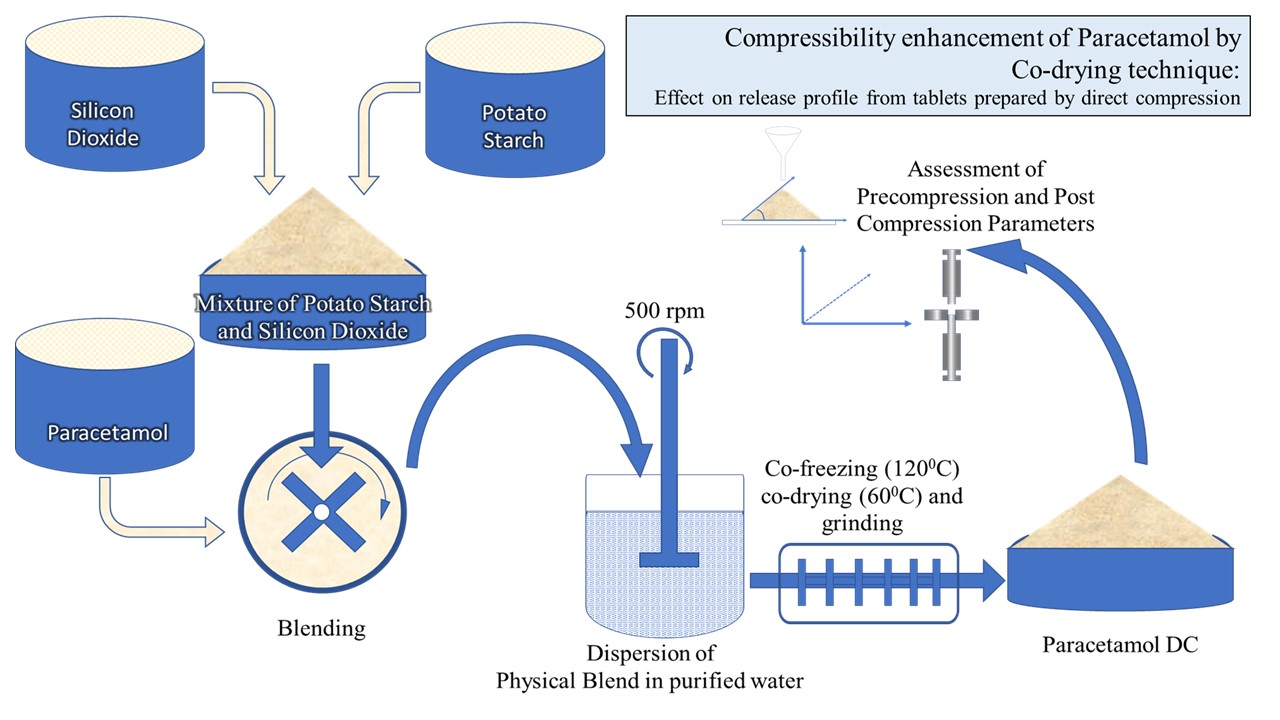

Direct compression is the most acceptable and preferred method for manufacturing tablets. However, the poor flow property and lack of the required compressibility of most active ingredients preclude the direct compression technique. Paracetamol is a widely used analgesic drug, usually formulated in compressed tablet dosage forms. It is a poorly compressible drug with a hefty dose, usually 300 to 500 mg. In addition, Paracetamol exhibits poor flowability and shows the tendency to cap on tableting due to its poor plasticity and compatibility. The present research work developed Paracetamol DC (Directly Compressible) by co-processing with a mixture of Potato starch and Silicon Dioxide in various ratios using co-freezing and co-drying techniques. Paracetamol DC was assessed for multiple pre-compression and post-compression tableting parameters. The marked improvement in flow behavior and compressibility of co-processed Paracetamol was observed. Results of studies showed that Paracetamol DC developed with a 10% mixture containing Potato Starch and Silicon Dioxide in a ratio of 7:3 exhibited better disintegration properties and released more than 50% of the drug within 30 min. The study concluded that the technique of coprocessing poorly compressible drugs such as Paracetamol with starch and silicon dioxide using the co-freezing co-drying technique could enhance the compressibility and flowability of active pharmaceutical ingredients.

Metrics

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Shreya Sham Naik, Sandesh Narayan Somnache, Ajeet Madhukar Godbole, Clecy Fernandes

This work is licensed under a Creative Commons Attribution 4.0 International License.